Frequently Asked Questions

Q-SUN Xenon Arc Test Chambers

Weathering and lightfastness test standards typically specify an irradiance level as both a magnitude and the wavelength (or wavelength range) where it is controlled. Irradiance in fluorescent UV and xenon arc weathering testers can be controlled using narrowband or wideband setpoints.

The selection of a narrowband control point in a QUV fluorescent UV tester is determined by the UV lamp type in use. For a Q-SUN xenon arc weathering tester, we suggest control using a wavelength or wavelength region in which the test specimen is sensitive. If the user is primarily concerned with color change, then a 420 nm control point is often used. If the primary area of concern is another type of physical property change, gloss loss for example, then a 340 nm control point is frequently used. A wideband TUV control point (300-400 nm) can be viewed as a compromise between the two narrowband (340 nm & 420 nm) control points, as it uses the total irradiance over the range 300 400 nm as its setpoint.

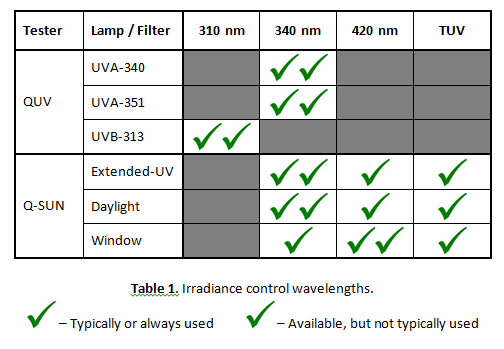

Selection of optical filters in a xenon arc tester also usually parallels this selection of irradiance control point. Typically, users testing with daylight optical filters use a 340 nm control point, while users of window glass optical filters generally use 420 nm control point. The available and most common selections for each lamp or filter type are presented in Table 1.

To read more about Q-Lab and to find more articles like this, please visit Q-Lab Blog.

You are now logged in to your account. You can now freely access all ( ) or (

) or ( ) documents. To access (

) documents. To access ( ) documents, please register your equipment here.

You are now logged in to your account. You can now freely access all (

) documents, please register your equipment here.

You are now logged in to your account. You can now freely access all ( ) or (

) or ( ) documents. To access (

) documents. To access ( ) documents, please register your equipment here.

) documents, please register your equipment here.