Background and Problem Statement

Q-Lab worked to develop a correlative accelerated and outdoor testing program for an American manufacturer of high-end outdoor furniture. This company’s products are commonly installed in public places such as shared office courtyards, cosmopolitan parks, and outdoor malls, similar to the example shown in Figure 1. The company prides itself, as many companies do, on its name and markets itself as a superior product in terms of performance and appearance.

Problem Statement

The manufacturer was experiencing many product failures when installed outside, even though the products were passing their accelerated laboratory tests (“false positives”). Luckily, this issue was found by their own outdoor exposure test performed at their manufacturing facility. This is a great practice for any weather test program and one Q-Lab highly recommends. This was an excellent pre-screen test that controlled the release of any new products and formulas, preserving the high quality and performance they promised.

The outdoor screening test discovered that a plastic component’s clear coat would turn white after one year of outdoor exposure. This was not evident in any of the accelerated testing conducted on their Q-SUN Xe-3 xenon arc tester running ASTM G155 Cycle 1. The customer even modified the test to an irradiance setpoint of 0.68 W/m2 @ 340nm, versus the 0.35 W/m2 @ 340nm that is specified, which is much more representative of so-called “noon summer sunlight.” Yet after continued and modified testing, the Q-SUN was still unsuccessful in replicating the defect.

Study

A comparison exposure in both the Q-SUN and QUV testers was performed by Q-Lab on small plastic plaques of the failing formula. The plaques were exposed in the Q-SUN to validate the results seen in the customer’s test. The QUV test was used to see if it offered better correlation to the outdoor exposure results.

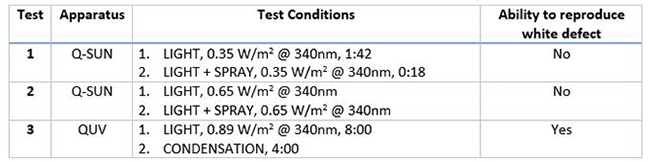

The Q-Lab Q-SUN exposure validated the customer’s findings. After exposing in a Q-SUN Xe-3 running a modified version of ASTM G155 Cycle 1, the white fading was not observed. However, the QUV tester running ASTM G154 Cycle 1, which cycles between 8:00 UV and 4:00 condensation steps, provided an almost identical match to the degradation feature experienced outdoors. The results of the comparison exposure are seen in Figure 2 along with a table, Figure 4, summarizing the tests applied.

One assumption for why the G155 test exposure was not recreating the outdoor failures was because of a lack of water exposure in the test cycle. The xenon standard is notably water deficient, with 18 minute spray cycles every 2:00. This is a stark contrast to the amount of moisture delivered in the QUV G154 test.

Conclusion

After the comparison test was performed and the results reviewed, the customer quickly purchased a new QUV tester. Testing their formulas in a QUV instrument running ASTM G154, the manufacturer was able to reliably produce the clear coat whiting in a shorter test time than they had been performing in their Q-SUN test that didn’t even produce the failure! The small investment in the QUV far outweighed the potential cost of a failure and loss of reputation.

The manufacturer continues to use both the Q-SUN and QUV testers, as complimentary test exposures, noting that ‘Our testers are always full’. The QUV testing they employed, now offers the ability to discriminate between high-performing and low-performing materials, which is a major benefit in quality control and product development. They were able to refine their clear coat formula and produce a product that was able to pass both accelerated tests, ASTM G154 & ASTM G155, and more crucially the outdoor exposure, as shown in Figure 3.

Figure 1: Typical outdoor furniture

Figure 2: Test formula which faded in both Outdoor and QUV exposure but not experienced in Q-SUN.

Figure 3: Alternative formula which passed all testing.

Figure 4: Test Conditions Applied